Breaking New Ground: The Rise of 3D Printing in the Automotive Industry

The automotive industry is at the cusp of a revolution. The advent of 3D printing technology is reshaping the way vehicles are designed, manufactured, and repaired, promising a future where precision, customization, and cost-efficiency reign supreme. But what does this mean for drivers, manufacturers, and the industry as a whole?

Section 1: The Emergence of 3D Printing in Automotive Manufacturing

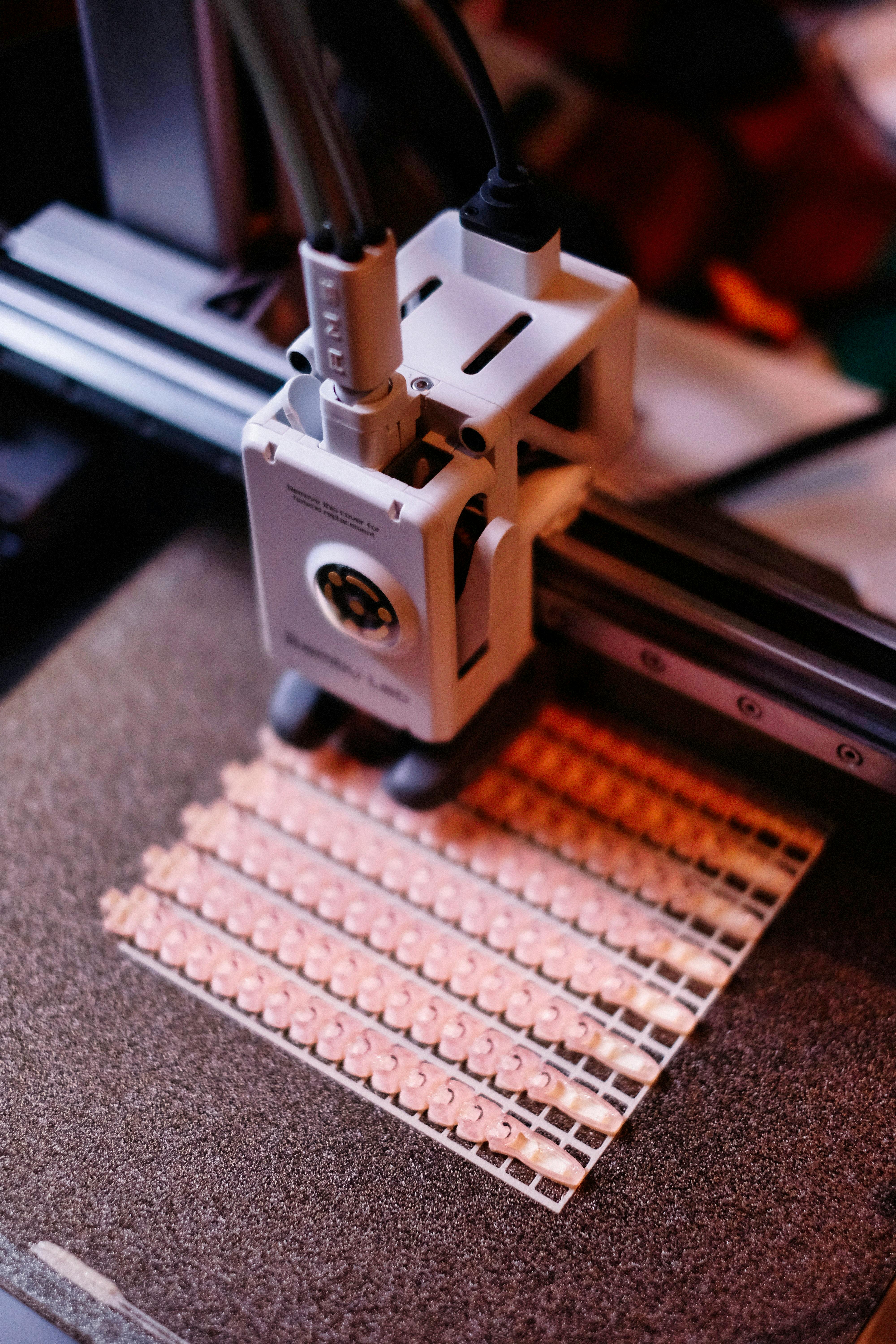

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from digital models by layering material in successive patterns. This technology, though in existence since the 1980s, has only recently begun to make waves in the automotive industry.

For decades, car production has been dominated by traditional manufacturing methods, which involve cutting, drilling, and molding raw materials into parts. However, these processes are often time-consuming, costly, and produce a significant amount of waste. With 3D printing, manufacturers can create complex parts efficiently and cost-effectively, offering a new level of flexibility and precision in car production.

Section 2: Current Trends and Applications of 3D Printing in Automotive

Today, 3D printing is used in various aspects of automotive manufacturing. It’s applied in prototyping, allowing designers to create and test new parts quickly. It’s also utilized for producing customized parts for high-performance vehicles and classic cars. More recently, 3D printing has been used to manufacture spare parts on-demand, reducing inventory costs and improving the availability of parts.

Furthermore, 3D printing enables the production of lighter and more complex structures, which can lead to vehicles with improved fuel efficiency and performance. This development is particularly significant as the industry faces increasing pressure to reduce environmental impact and meet stringent emissions standards.

Section 3: The Impact of 3D Printing on the Automotive Landscape

3D printing holds immense potential for the automotive industry. By reducing the time and cost associated with traditional manufacturing methods, it can drive down production costs and increase profitability. This technology also opens the door to greater customization, allowing manufacturers to offer personalized vehicles tailored to individual customer preferences.

However, the adoption of 3D printing also poses challenges. It requires substantial investment in new equipment and training, and there are still technical hurdles to overcome, particularly around speed and scalability. Moreover, as with any disruptive technology, it could cause job displacement in traditional manufacturing sectors.

Section 4: The Future of 3D Printing in Automotive

Despite these challenges, the future of 3D printing in the automotive industry looks promising. As the technology continues to evolve and become more accessible, it’s likely that we’ll see an increased use of 3D printing in car manufacturing. This could lead to more efficient production processes, more personalized vehicles, and potentially, a radical transformation of the automotive industry.

Section 5: Embracing the 3D Printing Revolution

The rise of 3D printing in the automotive industry is a testament to the relentless pursuit of innovation and efficiency. As we continue to push the boundaries of what’s possible, it’s clear that this technology will play a pivotal role in shaping the future of automotive manufacturing. For drivers, manufacturers and the industry as a whole, the potential benefits of 3D printing are immense. But as with all technological advancements, it’s how we embrace and adapt to these changes that will ultimately define our success.